Medical Device Reprocessing changes in sterilization procedures over the years

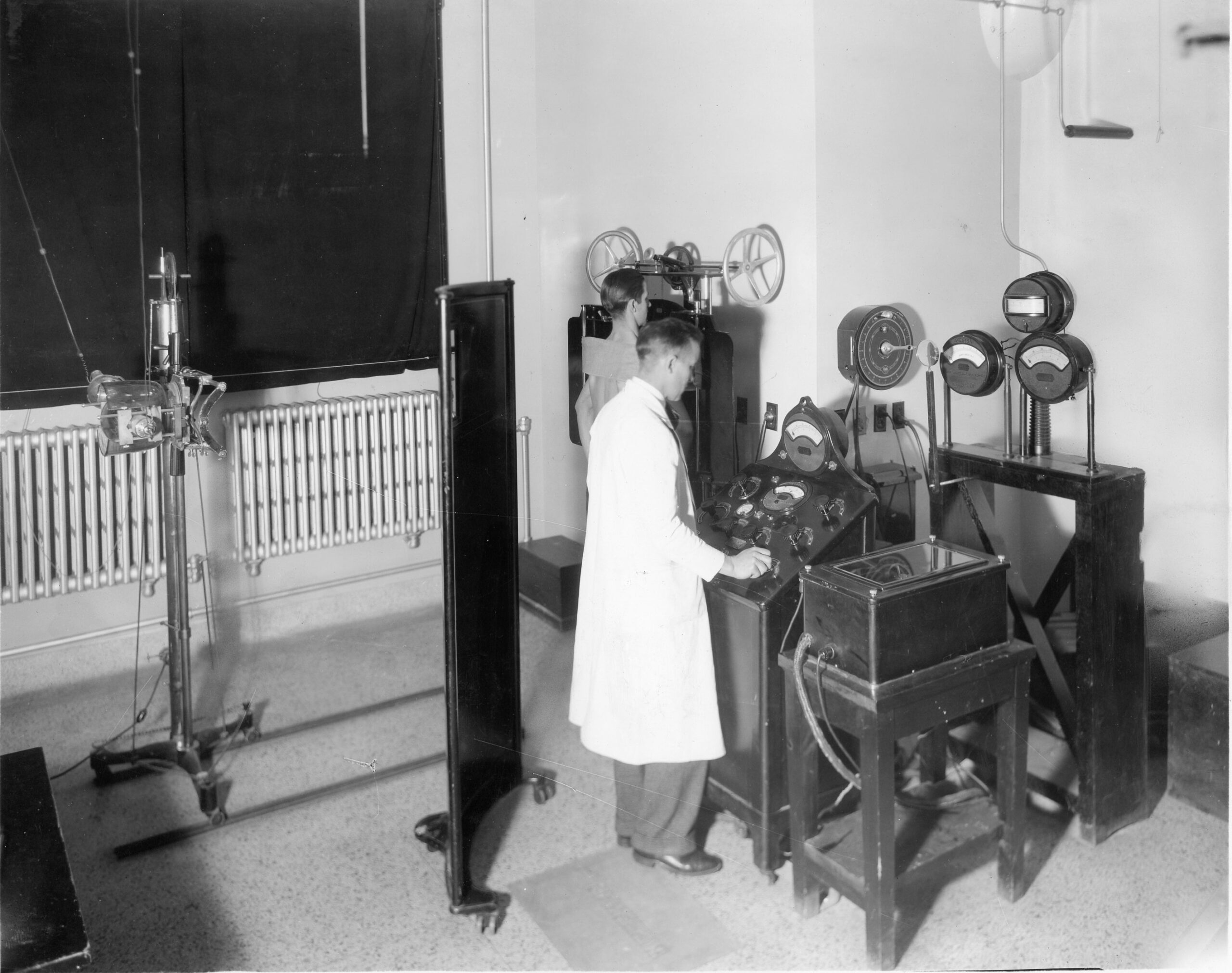

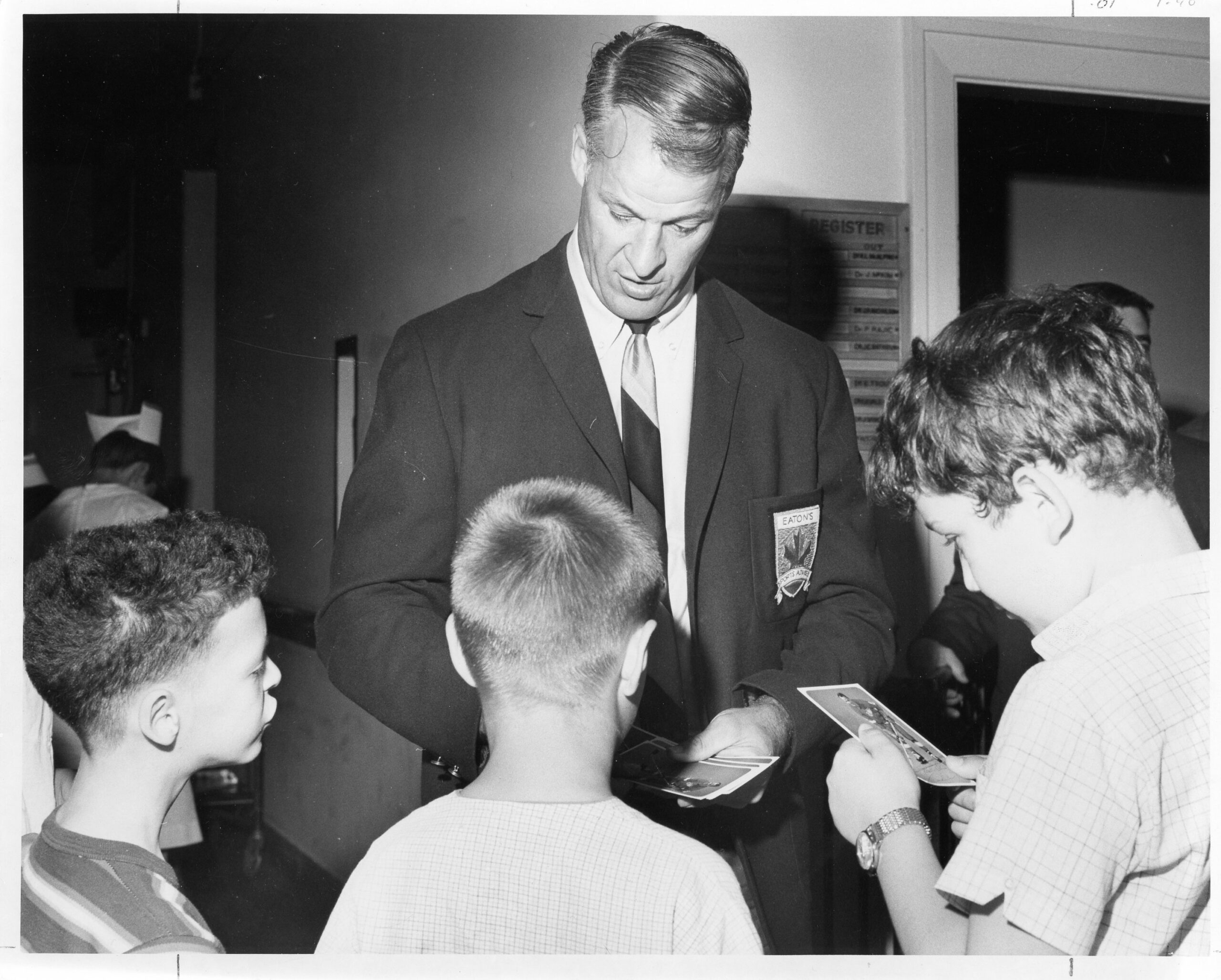

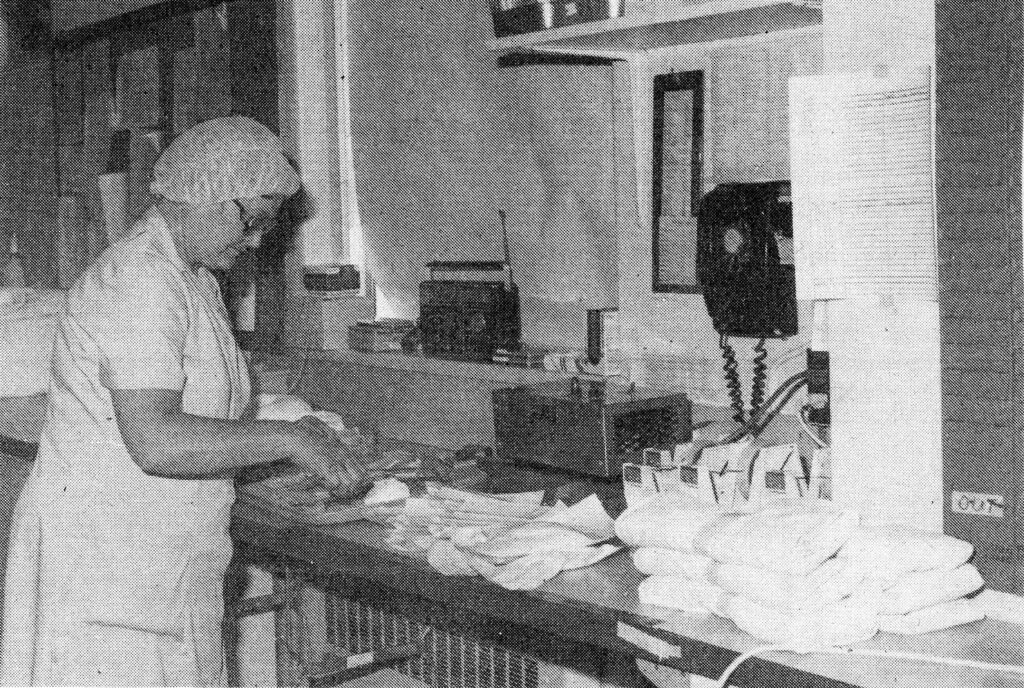

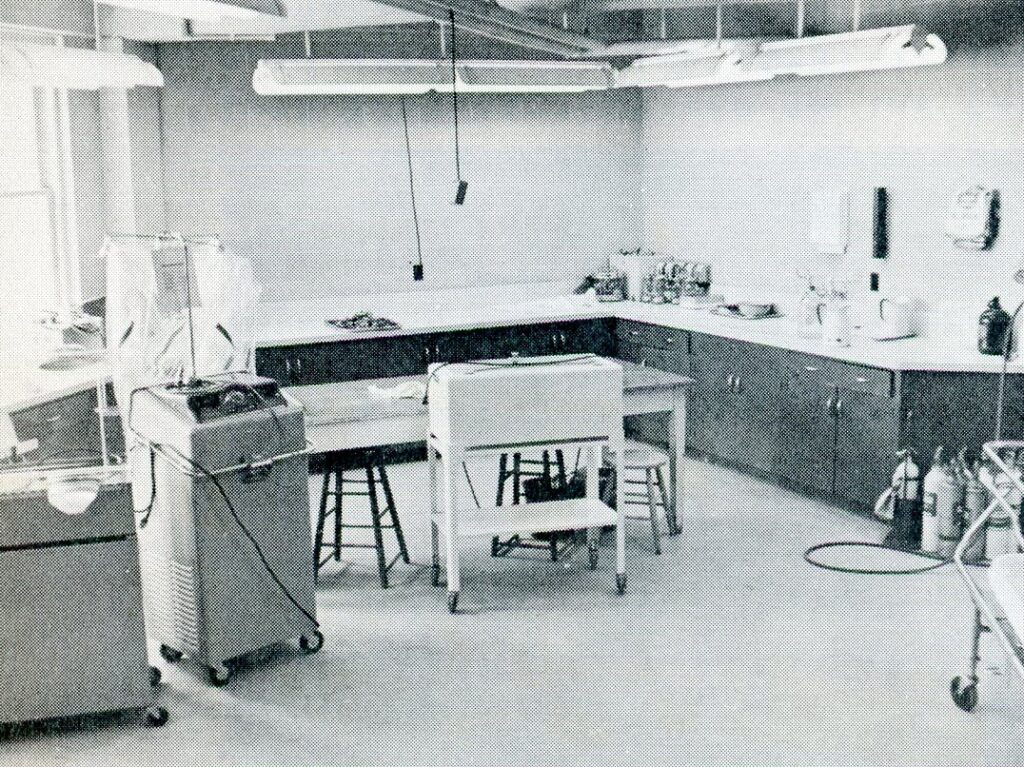

Above: Photo promoting the additional space for the Central Supply Room (CSR) from Vic Life magazine in 1967

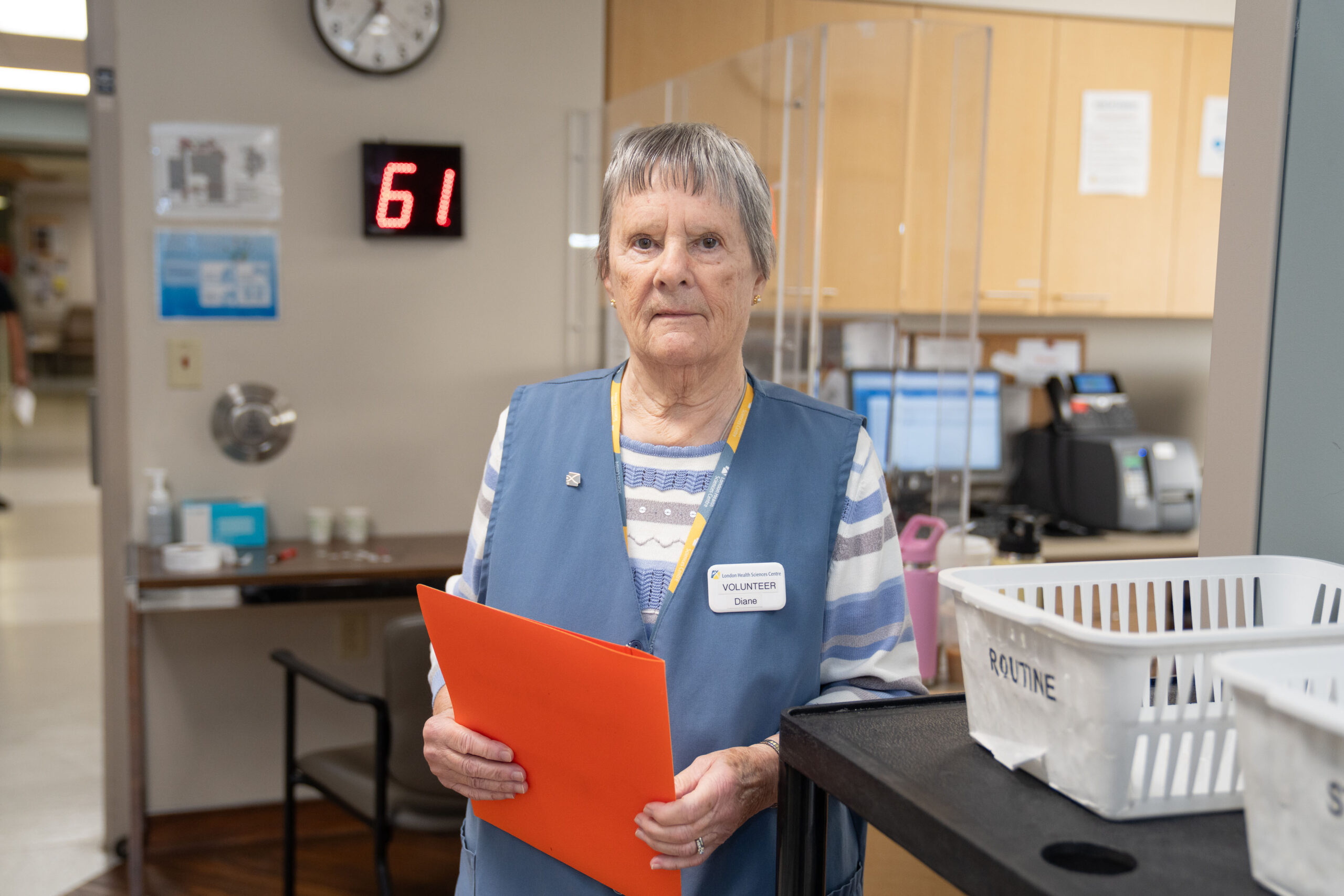

For the 150 years London Health Sciences Centre (LHSC) has provided care, improvements in sterilization and cleaning of equipment to prevent disease and infection have evolved. The department responsible for this has held various names, including Central Supply Room (CSR), Central Sterile Supply (CSS), Central Supply Department (CSD), Central Processing Department (CPD), Sterile Processing Department (SPD) and currently Medical Device Reprocessing (MDR) Department.

MDR technicians are certified professionals who ensure the highest level of patient safety by cleaning, disinfecting, sterilizing, and maintaining medical equipment. They inspect and test devices, track inventory, and ensure compliance with safety standards and regulatory guidelines.

The process of sterilization has changed significantly since LHSC first opened. A former nursing student, from Victoria Hospital’s School of Nursing class of 1888, shared her experiences and how they used to clean medical instruments in a letter to Vic-Life in 1960.

Sterilization was performed by boiling instruments and the use of carbolic acid and bichloride of mercury. The soap we used was harsh as compared with that used today and mustard was used for hand cleansing.

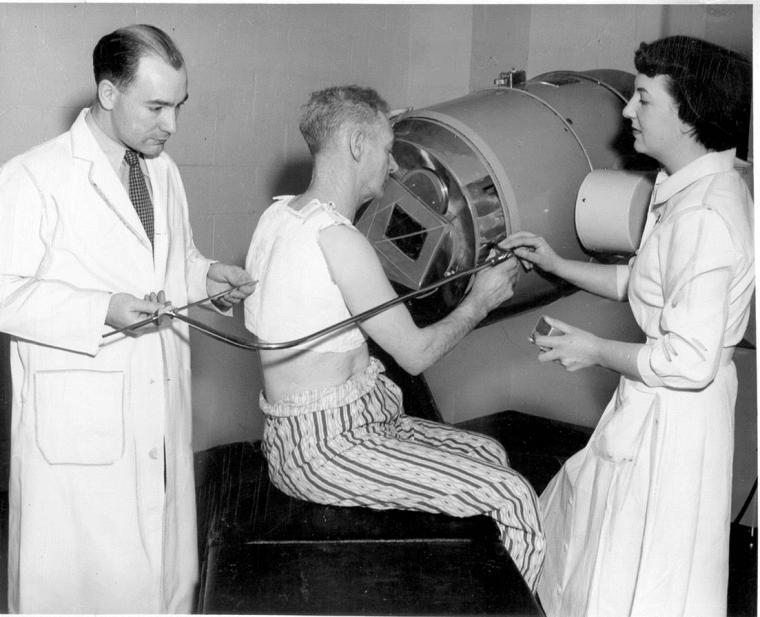

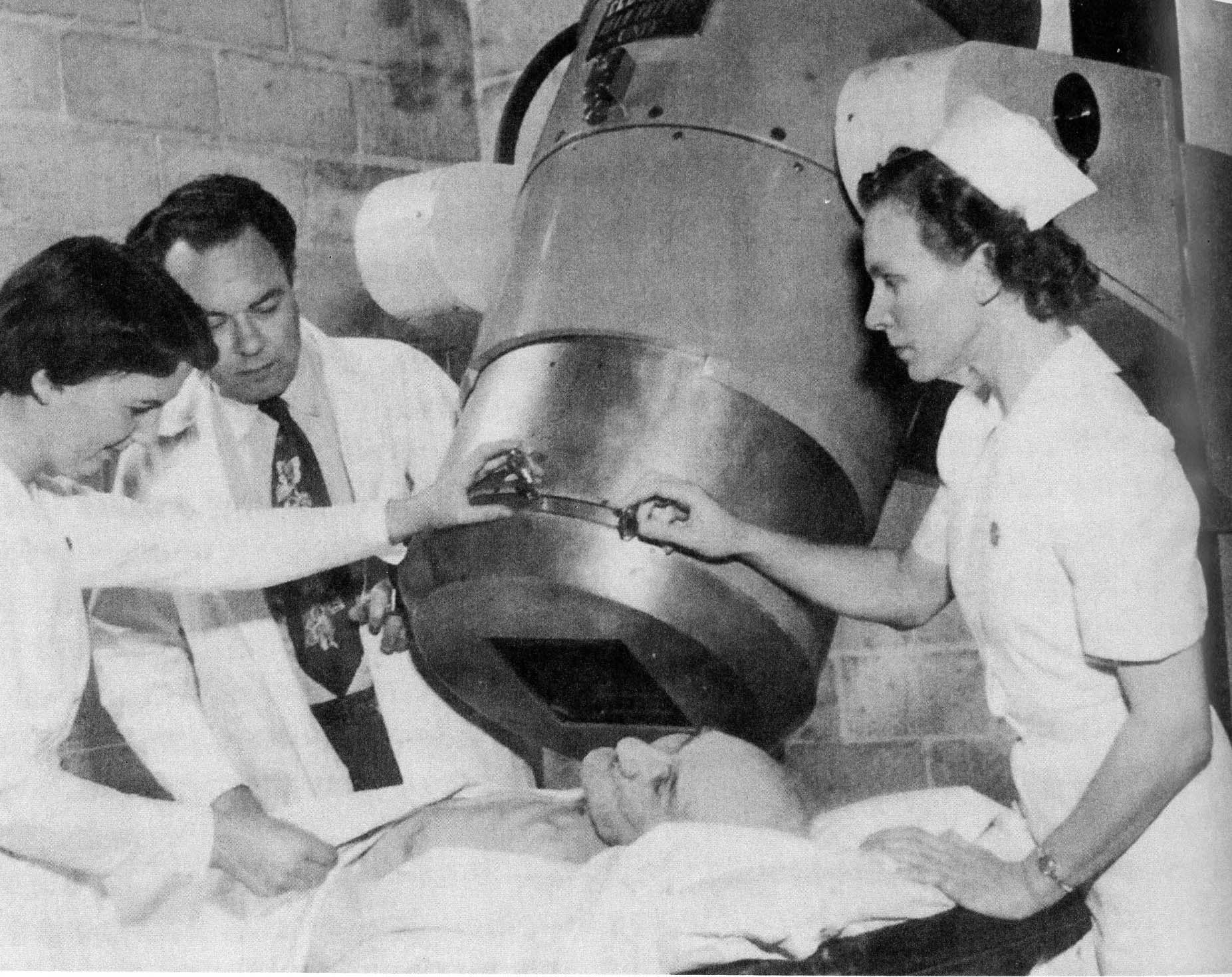

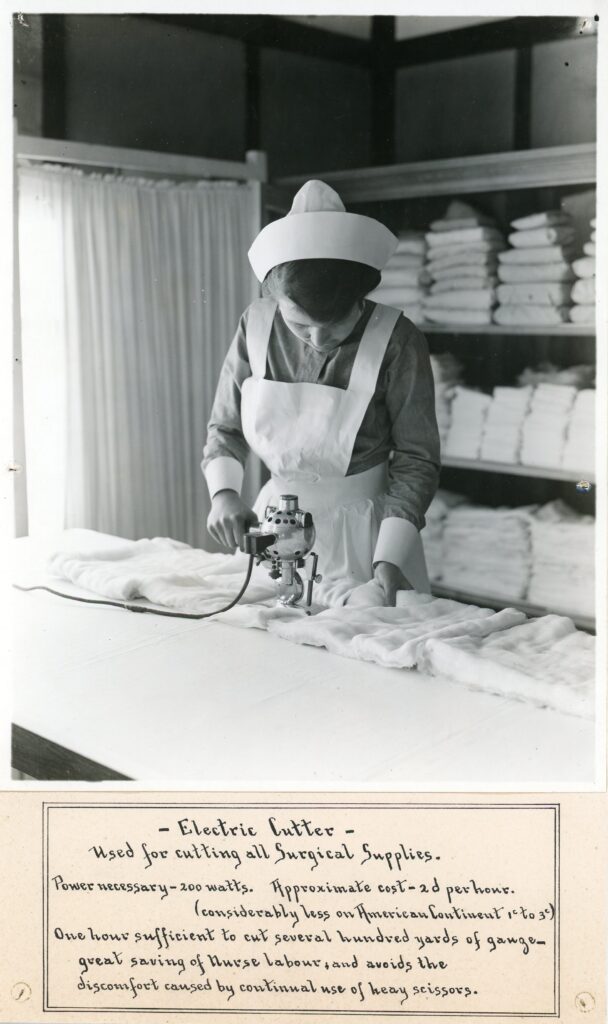

In the 1950s, tongue depressors, needles, gloves and even lamps were pieces of equipment the Central Supply Room (CSR) at Victoria Hospital used to routinely clean. Members of the CSR, which at the time included nurses, nursing assistants and ward helpers also made sterile dressings for patients.

The processes used for sterilization were steam, chemical (ethylene oxide) and dry heat ovens. The ethylene oxide required the materials to be aired out for 24 hours after sterilization due to potential risk to staff or patients for nausea, headaches, and skin burns. With advancements and knowledge in sterilization, ethylene oxide was replaced in the 1980s and 1990s with a hydrogen peroxide-based sterilization procedure.

In September 1949, the CSR department issued 56 trays holding multiple devices, such as scalpels or suture needles, for use in procedures. Today, MDR supports 122 to 145 cases daily in the operating room (OR) alone, most cases having multiple trays. In 1951, 5,341 trays were issued for the year. In 2024, the MDR sterilized over 295,000 trays.

Over three decades of rapid change

In 1988, staff member Alma Llamas joined the Central Supply Department (CSD) team at the Westminster site, now home to Victoria Hospital.

“At that time CSD was not involved with the OR or clinics; we cleaned and compiled basic trays for simple procedures,” explains Llamas. “The OR and clinic instruments were cleaned and sterilized by nurses, OR orderlies, and OR aides using flash sterilizers that were on units.”

Alma Llamas on the right in both photos, the first one taken around 1992 and the second photo with colleague Carla Hardy from 2025 in the MDR at Victoria Hospital

In the 1990s, CSD started to support the OR. This change began at Victoria Hospital’s South Street location where CSD would sterilize but still not assemble trays. At University Hospital, the department was called Central Sterile Supply, part of the Supply, Processing and Distribution Department. In 1988, following the merger between the two hospitals, the respective departments became the Sterile Processing Department (SPD).

“We started training and setting up supports for all services, from ORs to obstetrics, and then got involved in the clinics,” says Llamas. “We got automatic washing machines when we started supporting the OR and clinics.”

In 2005, SPD became the centralized location for sterilization and quality control. Shortly after, it was renamed to the Medical Device Reprocessing (MDR) Department.

Changes in technology and workflow

With advances in technology, such as scanners and computers, the team’s workflow has changed.

“Prior to desktop computers, we would have binders for each surgeon that listed all the surgeries they were skilled to do, and they would advise what surgery they were going to perform,” says Llamas. “We would go to their binder, find the surgery, photocopy the list and that would be how we would compile a tray.”

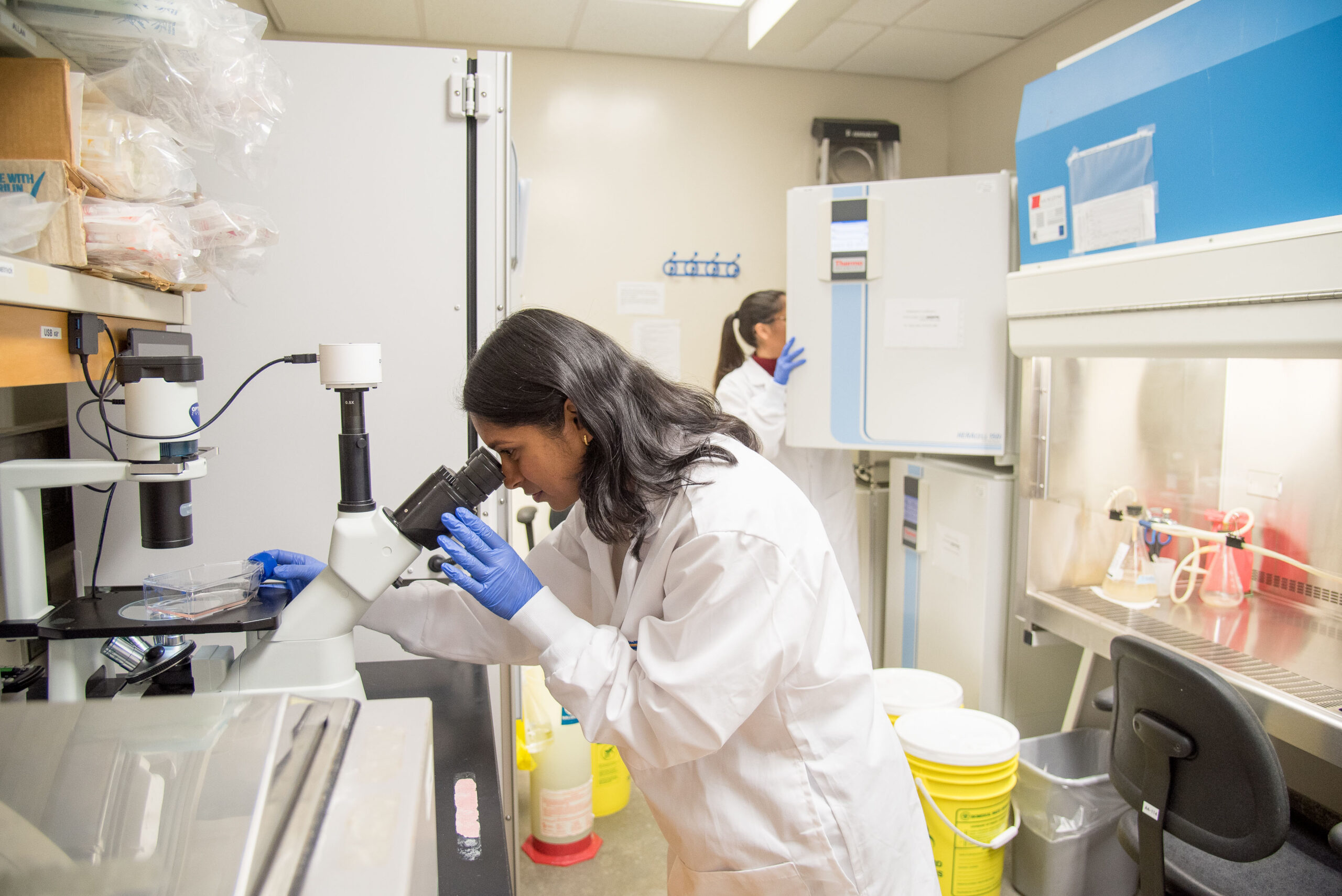

MDR photo taken in assembly area at Victoria Hospital in 1992 and the second taken in the same space in 2025 with MDR technicians Kady Hackett and Alana Rahman

Now it’s all digitized and the team has photos of how the trays should look. The changes in surgical procedures have also impacted the teams’ workflow. Occassionally there can be three to four different procedures combined. When this happens, the surgeons enter the procedures into the system, and it generates the list of instruments the team needs to compile and sterilize, known as the pick list. This digitization has improved the efficiency and accuracy of the MDR team; instead of having to locate and photocopy multiple pages from a binder the lists are automatically generated.

Changes in qualifications

MDR technicians have also seen a change in training and education.

“When I started, you did not need to have specialized training,” says Llamas. “Now it’s a minimum of a certification such as the one at Fanshawe College.”

Staff in MDR need to be pre-approved and taught on the safe handling and assembly of some of the instruments. The instruments have become more complex over the years, and the training has increased for disassembly, cleaning, maintaining and re-assembly.

“I’m very proud of our role in Accreditation; we are one of the first locations accreditors visit within a hospital. We are the heartbeat of the hospital,” explains Llamas. “Looking at the past, our responsibility as a department has increased, as have our responsibilities as technicians and it’s been so good.”

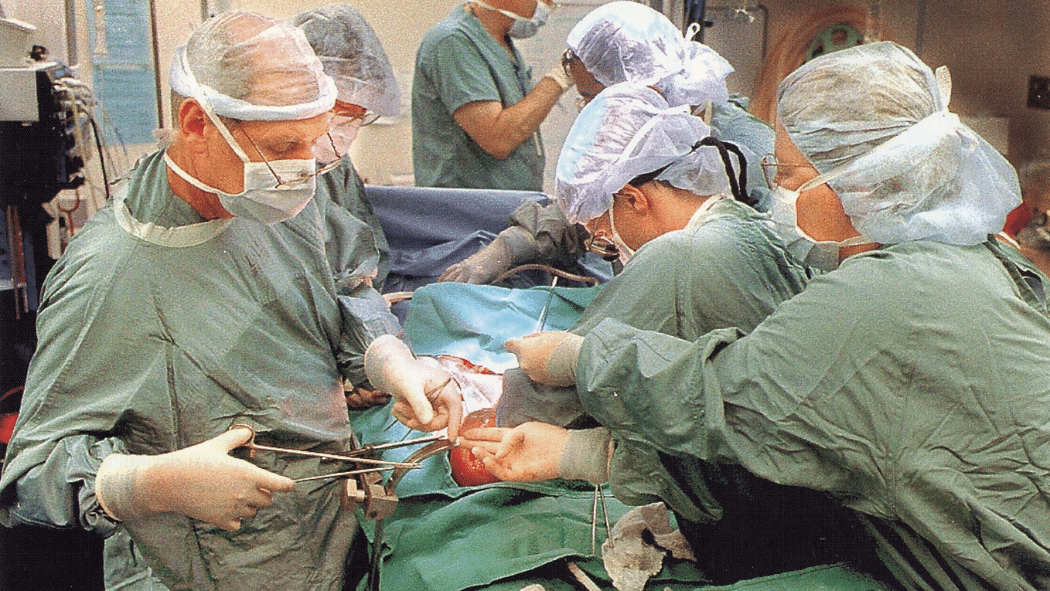

The process of sterilizing medical devices and equipment has changed over the years with advances in knowledge and technology. Today’s group of MDR technicians are specialized, certified team members who ensure the medical equipment is safely processed for use in all procedures from life-saving surgeries in the Emergency Department to life-improving procedures in the Nazem Kadri Surgical Centre.